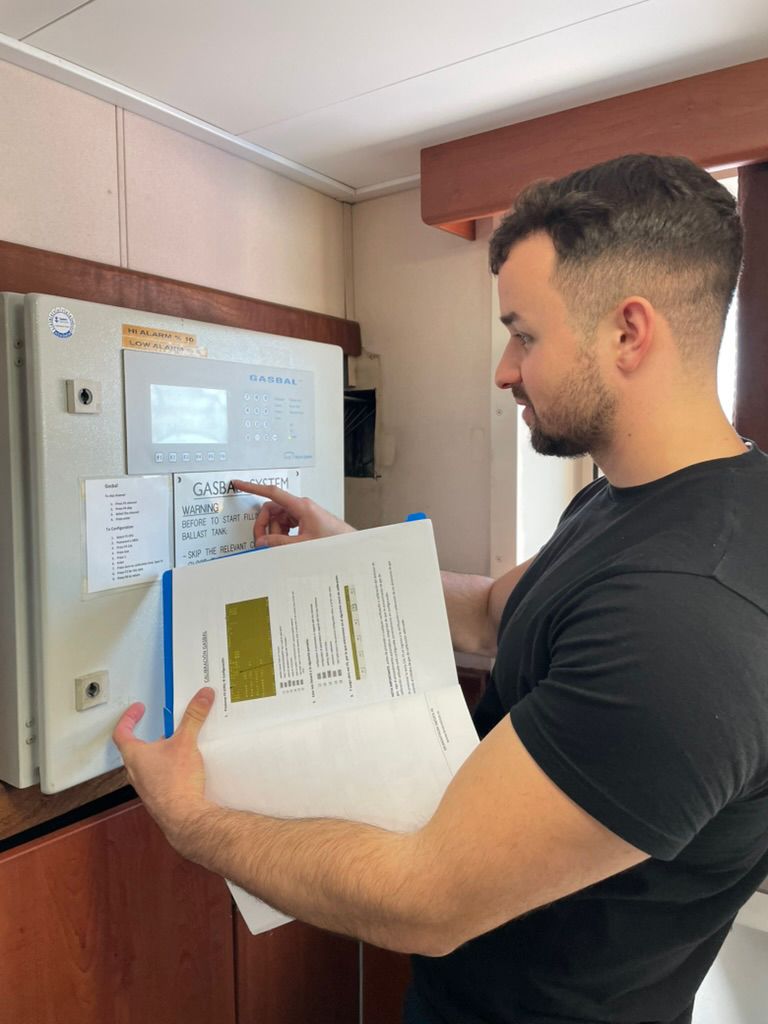

Sampling channels and alarms are verified onboard.

Ensuring gas detection systems are fully functional, calibrated, and correctly configured is essential for safe ship operations and regulatory compliance. Our IMS Hanla HGS-100 Gas Sampling System Service delivers the complete solution — from health checks and flow troubleshooting to calibration, configuration, and certification so your vessel meets ISM, IMO, and SOLAS safety requirements.

The Hanla HGS 100 fixed gas sampling system is engineered to monitor air in tanks, pump rooms, and void spaces and instantly detect gas levels that exceed safe, programmable limits. It integrates multiple sensors, sampling lines, alarm units, and flow indicators to deliver reliable and continuous gas surveillance. Proper calibration and setup not only ensure detection accuracy but also guarantee that audible and visible alarms activate correctly in hazardous conditions.

Gas detection isn’t just about installation regular calibration against certified span and zero gases is a key safety requirement under maritime safety codes. IMO and SOLAS guidance call for test and calibration procedures to be established in the ship’s Safety Management System and executed as part of ongoing maintenance.

Our service scope includes health check, full functional testing, certification, calibration, repair, and commissioning all available onboard or at major European shipyards including Gdansk, Rijeka, Valencia, Cadiz, Burriana, and Damen Rotterdam, among others.

With SIRE 2.0 inspections placing increasing emphasis on documented maintenance and calibration records, ensure your HGS-100 system is not only compliant but performing optimally. Reach out to schedule your service and keep your vessel’s gas detection systems safe, accurate, and inspection ready.